Horsch: proven first-hand

Soil is a living organism. At Horsch, they know, revere and practice this postulate. This year, AgroCentre has become an authorised dealer of Horsch machinery, and it has already arranged two client trips to the manufacturer’s facility in Germany.

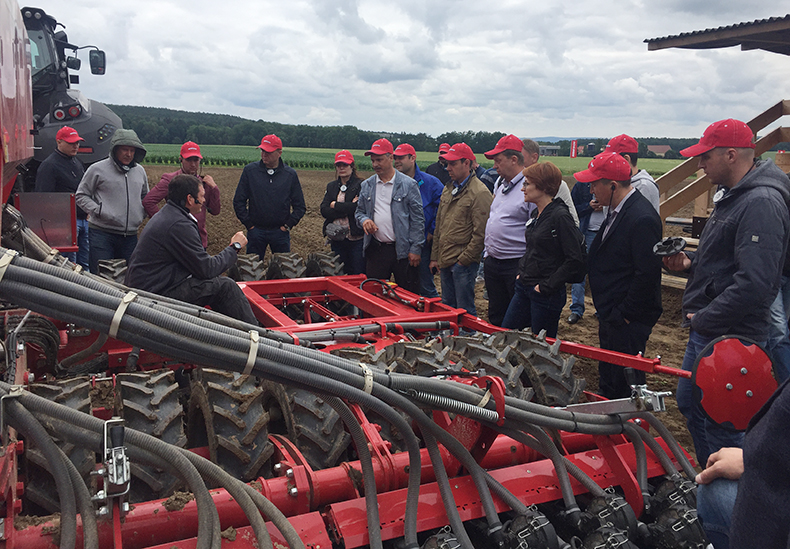

The members of the group from the Urals and Siberia became familiar with the tillage and plant protection equipment assembly process. They also had an opportunity to see the demo shows of the most outstanding machines. Upon arrival, the guests from Russia were warmly welcomed by Michael Horsch, founder of the company, who gave a presentation on the company’s activities. The communication continued with insightful lectures covering various agricultural topics and a discussion of global agricultural trends.

‘We were quite impressed with the field demonstrations’, says Dmitriy Gerasimenko, Head of Kurgan branch office of AgroCentreZakharovo. ‘We were shown practically the entire line-up, which is produced at the factory: from tillage equipment to major sowing units.’

The Horsch Maestro single grain seed drill was a magnet for the clients. It facilitates seed placement at a uniform distance, and fertiliser application close to the roots of the crops. A dedicated sensor and a radar ensure precision, slowing down the speed if necessary. The Horsch machinery is fully computerised, thus enabling online operation monitoring with any gadget and from any place.

‘We were dazzled with the Germans’ love of order and meticulousness, which certainly appealed to us’, says Oleg Kulikov, Director of AgroStimul (Kurgan oblast). ‘We have been fruitfully cooperating with AgroCentre for a long time, and Horsch has already caught our eye. We will definitely buy a Horsch Pronto 12 MT sowing unit. we expect that the machine will help us to improve our output and tillage quality.’

Horsch has a singular approach to work. Rather than churning out machinery copying design of the counterparts or following the latest trends, they go by their own know-how acquired through research and development.

‘Michael Horsch is a farmer himself’, says Denis Tyurin, Executive Director of AgroCentreZakharovo for Siberian Region. ‘All the products are built on the basis of inhouse developments. Product marketing starts only after the machinery passes rigorous testing on their own farms.’

The guests also visited fully automated warehouse. It is operated by a robotic stapler based on commands from dedicated software that is capable of finding any required part within a couple of minutes.

‘However at the Horsch factory, manual labour plays the central role’, says Dmitriy Gerasimenko, Head of Kurgan branch office of AgroCentreZakharovo. ‘The entire workflow is precise and aligned: manufacturing painting, and assembly of components, assessment by the quality control department. They take full responsibility for the quality of the machinery, which attests to its robustness and reliability.’

Besides, the group of clients visited another Horsch factory, specialising in the assembly of trailed and self-propelled sprayers. A true discovery for the guests was the so called ‘sprayer of the future’ featuring an auto steering system. Currently, the unique model is under development, but the Horsch experts expect it to take the farming world by storm soon.