With British accuracy

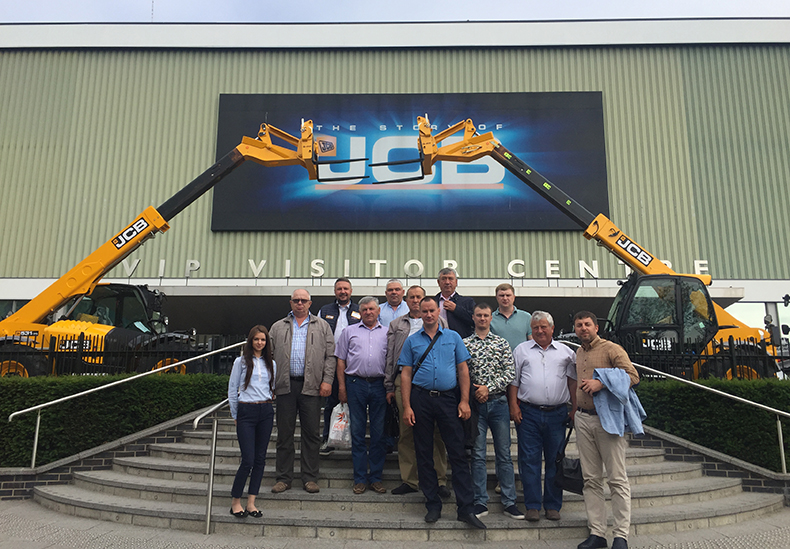

A group of AgroCentre’s clients and employees had a tour of the JCB production facilities used for the manufacturing of telehandlers in the village of Rocester, Staffordshire, England. The hosts welcomed the party of Russian visitors with an intensive business and cultural programme.

Today, JCB has 22 plants on four continents — 11 factories in the UK and manufacturing plants in India, Brazil, China, Germany and the USA. The primary goal of the visit was to gain an insight into the hi-tech assembly process and the latest innovations.

‘The programme of the trip was very intensive. It allowed our clients to take in the incredible scale of JCB production’, says Evgeniy Akulov, Sales Manager of AgroCentreZakharovo. ‘The sheer magnitude, British accuracy and historical continuity left them speechless.’

The tour started with the visit to the famous JCB Story Museum, which made a special impression on the members of the group. The Museum offers its visitors a fascinating journey through time. It takes you back to 1945, to the very garage where the success story of the world-renowned machine manufacturer Joseph Cyril Bamford starts. The idea of establishing his own business occurred to the 29-year-old Bamford in a period of despair, when he had lost his job. He bought a welding machine for 1 pound and, with its help, made his first invention — a backhoe loader.

‘The entire workflow is precise and aligned, which is one of the secrets of JCB’s popularity,’ says Sergey Dorofeyev, Sales Manager of AgroCentreLiski. ‘Due to the complete production cycle, the quality control department is capable of detecting any malfunction. JCB takes full responsibility for the quality of the machinery produced.’

JCB is also famous for its excellent quality service and after-sales customer support. AgroCentre’s clients were captivated by the World Parts Centre.

‘The World Parts Centre with the automated control system is a model of efficiency’, shares Vladimir Popov, Director of Znamya Rodiny agricultural enterprise (Altai krai). ‘They have achieved a high level of ‘off-theshelf’ parts availability and the ability to despatch non stock parts from the JCB World Parts Centre overnight, ensuring prompt processing of a dealer’s application and delivery of the required spare part, even if the model is no longer in production.’

JCB is continuously improving its automated system of after-sales management, maintenance and control to keep up with the customers’ needs. Vladimir Solovyov, Director of ‘Vozrozhdeniye’ agricultural enterprise (Kursk oblast), is also quite satisfied with this solution.

‘Following the sale, the manufacturer controls the condition and performance of the equipment online. This is a new trend, which definitely gives the clients a considerable advantage.’

JCB has been installing the special system, fully monitoring the location and the parameters of the machines, on all the models of telehandlers for five years now. It sends instant notifications when service is due and critical alerts in case of serious mechanical or electrical issues directly to the factory in the UK. Thus, the experts at the JCB head quarters can promptly sort the issue out and provide the guidelines to the dealer to ensure the machine is fully operational as soon as possible.

The tour included a demo show of the JCB machinery, which dispelled any doubts as to its exceptional performance and innovative design.

‘We saw the JCB 531-70 Agri Pro and JCB 541-70 Agri Pro telehandlers featuring a new transmission in operation’, says Sergey Lomantsov, Executive Director of AgroCentreLiski. ‘JCB has launched a dual-mode gearbox that effectively combines the best aspects of the hydrostatic transmission and the powershift technology. The machines with the DualTech VT variable transmission has fast response and fine speed adjustment at lower travel speeds. They are superior to other models in manoeuvrability and versatility.’

Another novelty is the JCB front-end loader with the articulated frame and telescopic boom which make it highly manoeuvrable and suitable for virtually any farming tasks.

Besides the tour of the JCB factory, the clients had a unique opportunity to visit an organic farm, where the descendants of Joseph Cyril Bamford practice organic livestock farming.